The speed at which changes in the environment are occurring means that businesses must rethink their model and become more flexible, agile and efficient than ever before. To achieve this, the Lean methodology ensures that, by applying its 5 principles, it is possible to be more productive with fewer resources.

Be sure to read this post to learn about the Lean principles that will help you optimize your business and how some technologies such as electronic signatures can add value and improve your results.

What is Lean methodology and where can it be applied?

The Lean method originated in Japan, within the production line of Toyota, one of the largest producers in the automotive industry. The principles of this philosophy are based on eliminating any unnecessary expenses in order to maximize value creation. To achieve this, it is necessary to get rid of those activities that do not add value to the process or to the customer, the so-called mura, muri and muda. The first concept represents the variation caused by lack of standardization, the second represents overload and the third represents waste or useless activities.

If we talk in terms of benefits, this innovative philosophy of managing processes contributes to the improvement of productivity and company performance, increases customer satisfaction levels and reduces costs and the need for inventory.

Within processes, Lean thinking has been much more oriented towards optimizing production systems by applying methodologies and tools typical of Lean Manufacturing, also denominated as Lean Production. However, its success in improving competitiveness has shown that this methodology is an essential factor for business growth and survival, so it has not taken long to be exported to other industries, and it has done so transversally to all areas of companies.

As a result, different interpretations of Lean Manufacturing have emerged outside the productive aspect. In terms of business management, Lean Management is an evolution of the Lean philosophy that focuses on the organization's performance, always supported by the concept of continuous improvement. The Lean culture also allows business and product development. With the Lean Startup method, based on "validated learning", it is possible to gradually verify the hypotheses before having the final product, increasing the probability of success of a business.

Basic principles of Lean methodology

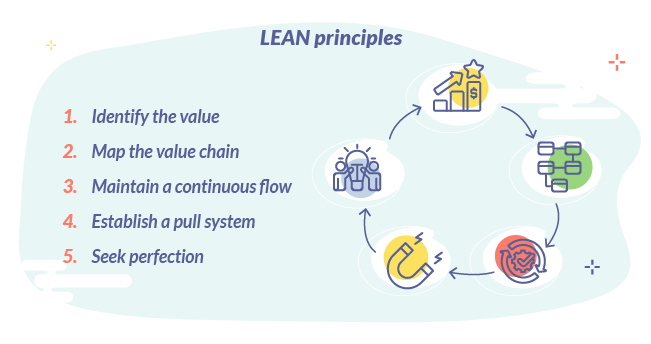

In this context, the Lean methodology is based on 5 principles that can be applied to improve any business:

1. Identify opportunities and generate value. This principle is essential. The product or service must be something that the customer wants and is willing to pay for.

2. Map the value chain. Value is the result of the sum of a series of activities and operations. A structural analysis of all the phases involved in production and marketing must be carried out, identifying the sources of waste in order to minimize or even eliminate them.

3. Maintain a continuous flow. To this end, it is necessary to identify bottlenecks and alleviate them, distribute the amount of work avoiding multitasking and saturation and eliminate obstacles.

4. Establish a pull system. That is, new work is only started when there is a demand that justifies it and there is available capacity, as opposed to the push method, in which the product is pushed into the market without demand.

5. Seek constant improvement. The objective is to continuously optimize each process in pursuit of perfection. The focus should be on improving activities that generate more value while discarding as much waste as possible.

Technology must add value to the process, the customer or both

Lean is a cultural approach, a different way of seeing and doing things. Within the set of techniques and tools, digitization and the use of technologies applied to processes can become a key factor to successfully transfer the Lean approach to business activities.

Following the fundamentals of the Lean philosophy, it is possible to state that too much technology is useless. In general, the tendency of organizations is to massively adopt existing and emerging technologies without assessing whether they are really necessary.

It is essential to seek a balance between technology, philosophy and culture. In line with the basic principles of Lean methodology, the technology applied must add value to the process or to the customer and get rid of useless or unproductive activities. As we will expand on below, Uanataca's electronic signature solutions make processes more efficient, more productive and less costly.

Uanataca's e-signature solutions: less effort, better results

Uanataca's e-signature solutions follow the basic principles of Lean, ensuring that with their use:

- You will generate value : to generate value it is necessary to orient the business to the customer and not the other way around, Uanataca's signature solutions are designed to offer the best customer experience before, during and after the signature.

An end-to-end digital experience, its security and usability are differentiating values of Uanataca's solutions that put the customer at the center.

- You will discard activities that do not add value, and you will be able to free up resources to devote to those that do.

In paper-based signature processes, there are many unproductive tasks that do not add any value, but do consume resources, for example, printing documents. On the other hand, the electronic signature is a paperless process with value throughout the chain and for all parties: on the company's side, processes are streamlined, costs and environmental impact are reduced; on the user's side, he will avoid unnecessary travel and will be able to sign from anywhere and at any time.

- You will eliminate repetitive tasks and those critical points where bottlenecks tend to occur, or at least alleviate them. Often, in paper-based signature processes, the need for physical presence slows down the flow and delays the time of signing. This bottleneck can lead to considerable losses for the company. With electronic signatures, documents can be signed instantly, even if the signatories are in different countries.

In conclusion, the LEAN methodology will make it easier for companies to evolve towards a more advanced management model. Undoubtedly, reducing waste, improving quality and eliminating inventories will make it possible to work better, faster and easier. Moreover, if your goal is to increase your company's productivity, digital transformation is the key.